September 29, 2023

Powder Coating Perfection

When it comes to outdoor site furnishings, quality and durability are paramount. Powder coating is one of the primary ways to protect steel furnishings and ensure outdoor durability. For this reason, we made a decision back in 2001 to bring our powder coating line in-house to have complete control over our final product quality. Owning and operating our own powder coating line has been a manufacturing advantage that allows us to achieve the highest level of quality control, production efficiency, and powder coating perfection.

By adapting to advanced technologies and continuously improving equipment throughout our production facilities, our Keyshield® powder coat finish has certainly become something to write about and a true differentiator in the site furniture industry. In this blog, we will take a closer look at Keystone Ridge Designs’ powder coating and how we have perfected the process to create unmatched standards of excellence for steel furnishings.

In the previous blog, “Why Powder Coat”, we discuss the general benefits of powder-coated products but it is the details of our step-by-step process that earn us a superior reputation of quality.

The Powder Coating Process

In its simplest definition, powder coating is a method of applying a protective and decorative finish to metal surfaces to create a beautiful, high-performance finish. Keystone Ridge Designs masters this technique through every stage of our site furniture powder coating process.

1. Surface Preparation

The journey to a high-quality powder coat finish begins with meticulous surface preparation. We take great care to smooth, clean, and treat steel surfaces to ensure our products are free of contaminants like rust, oil, and dirt. This is done through both steel shot blasting for a smooth surface and sandblasting to remove any remaining contaminants. It is a crucial step that directly affects the adhesion of powder coating.

2. Pre-Heat

The raw product then receives a corrosion-inhibiting phosphate coating that continues through a dry-off and pre-heating process. This pre-heat further prepares the product for a more effective bond of our two-coat powder application.

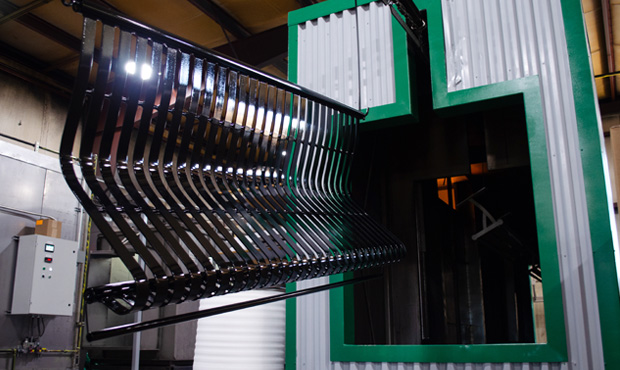

3. Powder Application

An electrostatic spray gun is used to apply a fine powder coating to the steel components. The first coat is a zinc-rich epoxy powder primer. The second coat is the colored polyester powder coating. Both coats are electrostatically applied to an industry-leading thickness to create an even and consistent coat.

4. Curing

After the powder is applied, the products continue through the line to a 425-degree oven where they undergo the final curing cycle. During curing, the powder chemically reacts and fuses to the steel, creating a smooth, durable, and resilient finish. This curing process ensures the coating is highly resistant to chipping, cracking, peeling, corrosion, or UV damage. It is where the final product begins to shine in its vibrant, glossy finish.

The KEYSHIELD Advantage

The advantage of our KeyshieldTM finish is not only found in the process but also in the people who take great pride in that process, the equipment, and the end product. Our team works tirelessly to keep our line running smoothly and looking good. It is the attention to detail of our employees that makes sure every product passes inspection and has been coated to perfection.

Throughout the manufacturing evolution of Keystone Ridge Designs, we have made numerous upgrades to our powder coating line to increase capacity, improve the thickness of our coating, prevent rusting vulnerabilities, and ultimately ensure client satisfaction.That brings us to where we are today with a state-of-the-art facility that utilizes cutting-edge technology and skilled operators to coat hundreds of benches, litter receptacles, bike racks, table sets, and other site furnishings every day. When you invest in Keystone Ridge Designs steel site furnishings, you’re not just getting outdoor furniture, you’re investing in long-lasting quality that enhances outdoor spaces. And our powder coat finish is one of the main reasons why.

ARCHIVES

- Proudly Made For America's Public Spaces

- Summer Starts Outside

- Site Furnishings In Historic Streetscapes

- Tourist Destinations: Taking A Seat At America's Top Attractions

- March Maintenance: Preparing Public Spaces for Peak Season

- Why Quality Matters: The ROI of High-End Site Furnishings

- The Best Time to Invest in Outdoor Furnishings

- Celebrating 100 Blogs

- Hidden Site Furniture Gems: Unique Offerings from Keystone Ridge Designs

- Designing Cohesive Outdoor Spaces with Coordinating Site Furnishings

- The Role of Benches in Public Spaces: More Than Just Seating

- Site Furnishings With Custom Colors - Creativity With Color

- American Makers: Celebrating Our Site Furniture Manufacturing Team

- Love Letter To Litter Receptacles

- The Unique Beauty And Benefits Of Wood-Grain Aluminum By Keystone Ridge Designs

- Keystone Ridge Designs Celebrates World Landscape Architecture Month

- Sustainability At Keystone Ridge Designs

- Mix And Match Site Furniture Designs

- Planning For Planters

- Downtown Decorations: Deck The Streets With Benches & Holly

- Customized Site Furniture Solutions: How To Tailor Site Furnishings To Fit Your Space

- The Making Of A Streetscape

- Powder Coating Perfection

- Project Highlight - UPMC Mercy Pavilion

- Sing A Song Of Site Furnishings

- Transit and Bus Stop Furnishings

- Project Highlight - Latrobe, PA

- Litter Receptacle Lid Options

- Site Furniture Design Details

- Park Furniture

- What's New for 2023

- Trade Show Trips and Trends

- Giving Thanks And Giving Back

- What Are Site Furnishings?

- #FridayFabrication

- Outdoor Furniture For Schools

- Keystone Ridge Designs Top Sellers

- Site Furniture & Urban Design

- Production With Purpose

- Outdoor Chairs for Public Spaces

- Project Highlight: Cape May County Open Spaces

- Site Furniture Sets

- Residential Development Outdoor Trends

- ASLA Expo Recap

- 25 Years of Outdoor Furniture (Part II)

- Healthcare Site Furniture Trends

- Project Highlight - The Highline Pittsburgh

- Tips For Buying A Memorial Bench

- Zoo Furnishings

- Guide To Custom Signage And Graphics

- Outdoor Church Furniture

- Site Furniture Standards

- What Is A bollard?

- Outdoor Furniture For Ski Resorts

- Commercial Outdoor Furniture Trends for 2021

- 2020 Greatest Hits In Site Furnishings

- Design Timeline - Patented Site Furniture

- Spotlight On Garden Furniture

- 25 Years Of Outdoor Furniture

- Unique Outdoor Spaces

- Tips For Choosing Commercial Outdoor Table Sets

- Project Highlight - Longevity Bench Project

- Promoting Healthy Outdoor Spaces

- Signs Of Spring

- Project Highlight - Pianos About Town

- Powder Coating Color Trends

- All-Weather Site Furnishings

- Top 6 Traditional Commercial Bench Designs

- Top 9 Modern Outdoor Benches For Commercial Settings

- Made In The Shade: Choosing The Best Commercial-Grade Umbrella

- Outdoor Seating Alternatives: Think Outside The Bench

- Project Highlight - The Tracks At Brea

- Sites Of Summer

- Fundraising With Furnishings

- Durable Site Furniture - What Does That Mean?

- Customization 102

- New For 2019

- How It's Made

- Fall Photos And Furnishings

- Site Furnishings For Senior Living

- Project Highlight - Echo Park Lake

- Park Bench Workout

- Site Furniture And Planning For Public Safety

- The Art Of Bike Racks

- Site Furniture Materials 101

- What's New?

- Project Highlight - Carson City Revitalization

- Reducing Waste - It Takes All Sorts

- Putting The Fun In Furniture

- Site Furniture Placement Guidelines

- Project Highlight - City Of Weston, FL

- Focus On Photography

- Thankful At Thanksgiving

- How To Accessorize Your Landscape

- Why Powder Coat?

- Top 5 Unusual Customizations

- Site Furniture For Kids

- Customization 101

- Project Highlight - McCandless Crossing

- How To Save Money On Site Furniture

- Christmas With Keystone Ridge Designs

- Retail Branding

- Halloween Costume Ideas

- The Benefits Of Steel Site Furniture

- A Campus Standard - Why It's Important

- Guide To Plaques

- Four Trends In Site Furniture